FLAX

Flax is a naturally grown raw material. It is one of the oldest known raw materials, and can be traced back 30,000 years when it was used by prehistoric man. Anecdotal evidence has it that Egyptian priests dressed exclusively in linen (made from flax), as it was considered a symbol of purity.

Today, it still remains an organic raw material, supporting ecological, sustainable agriculture – thus also representing a 'pure' raw material. Growing flax requires little or no herbicides or fertilisers, further contributing to the sustainability equation.

- Naturally grown, an eco-friendly raw material

- Supports ecological, sustainable agriculture

- Can be used for structural applications

- Good sound deadening qualities and does not conduct electricity

- Can be used in aesthetic interior applications

- Can be pigmented for a variety of colours

BALTIC 68 CAFÉ RACER

The first yacht of this size to be built using flax, the eco-friendly hull material. 50% of the hull structure will use naturally grown flax significantly reducing the yacht’s environmental impact. Apart from being an eco-friendly raw material, Bcomp’s ampliTex also has excellent sound deadening properties enabling us to further reduce weight.

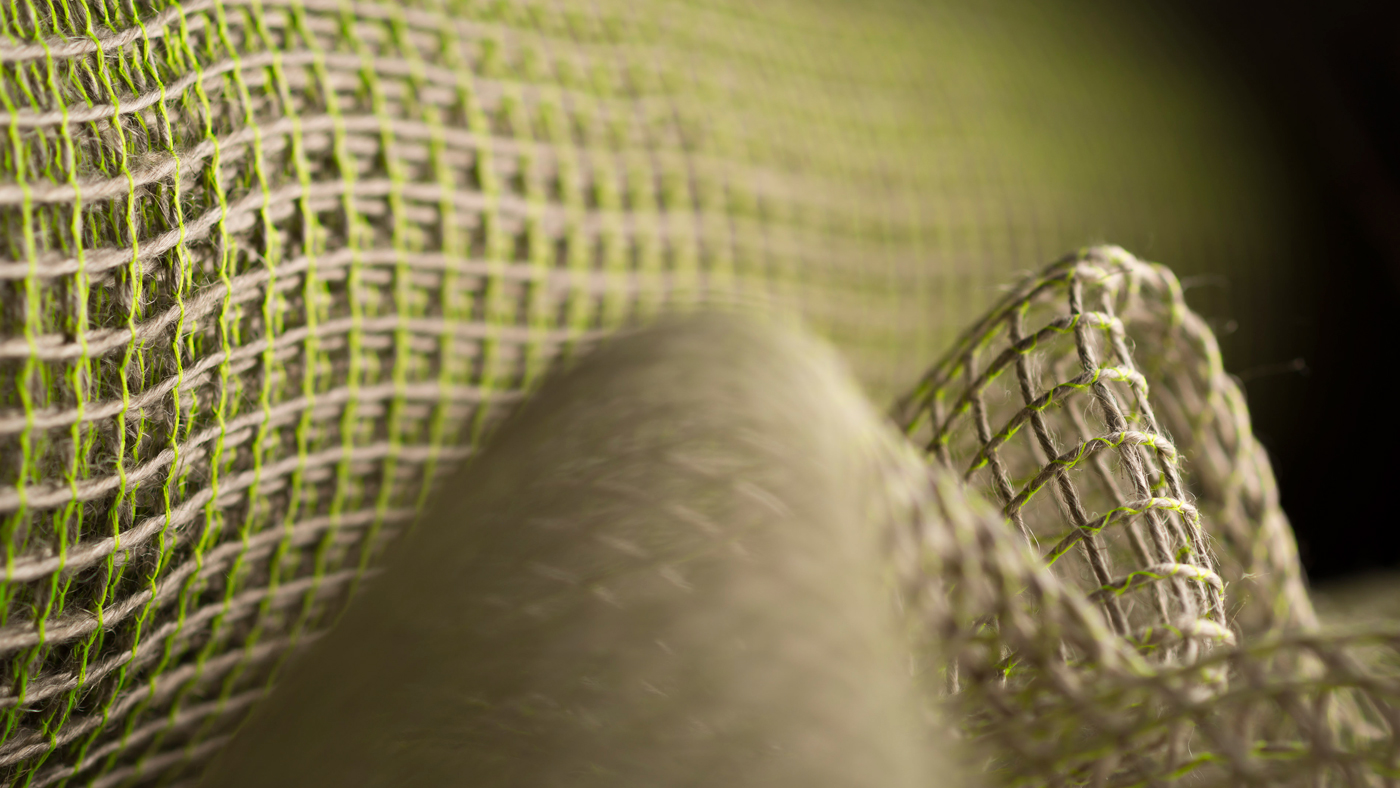

WHAT DOES IT LOOK LIKE?

Visually, flax-based surfaces have an appealing, organic tactile look and tactile feel. As flax can be dyed and pigmented, the variations are endless. Flax also has many beneficial properties for boat building, offers versatility for interior applications and has natural sound deadening properties. We have built several boats using flax in a number of ways, including structural and aesthetic applications, but we feel we are still at the early stages of an exciting journey exploring the limitless opportunities presented to us by this wide ranging, ecologically acceptable technology.

SUPERYACHTS

For larger yachts we are not yet using flax in structural applications, but we expect to be able to make significant inroads in the near future, reducing the use of carbon fibre to a previously unseen extent. For yacht construction, flax as a reinforcement is ideally suited to the construction of many components, including cable tray mouldings, partly because of the lack of conductivity, interior paneling, shelves, floorboards and support construction.

IN-HOUSE R&D

Currently, Baltic Yachts uses the ultra-light combination of carbon skins and foam cores in floorboard panels. The aim is to reduce the amount of noise insulation required with the help of these natural materials like flax, which have the ability to absorb vibration.

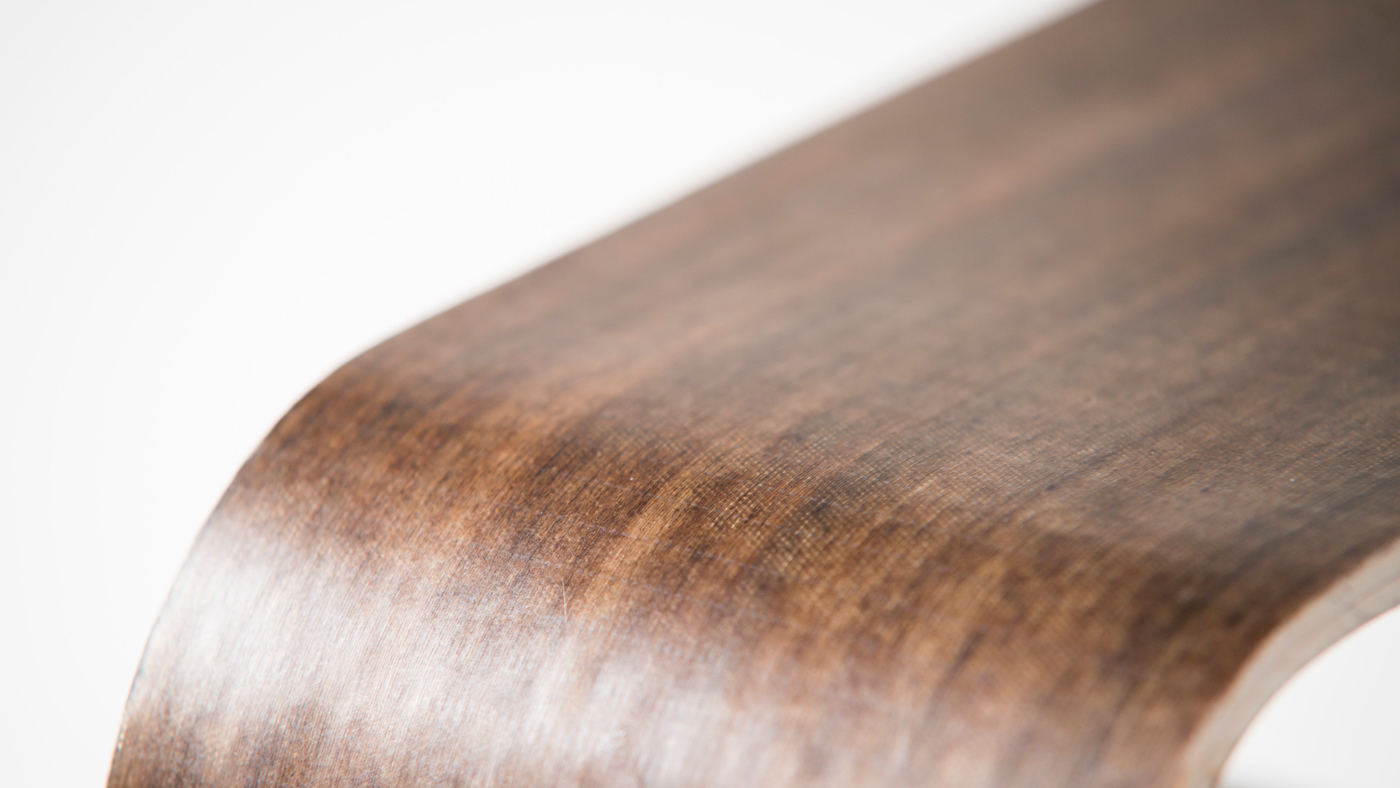

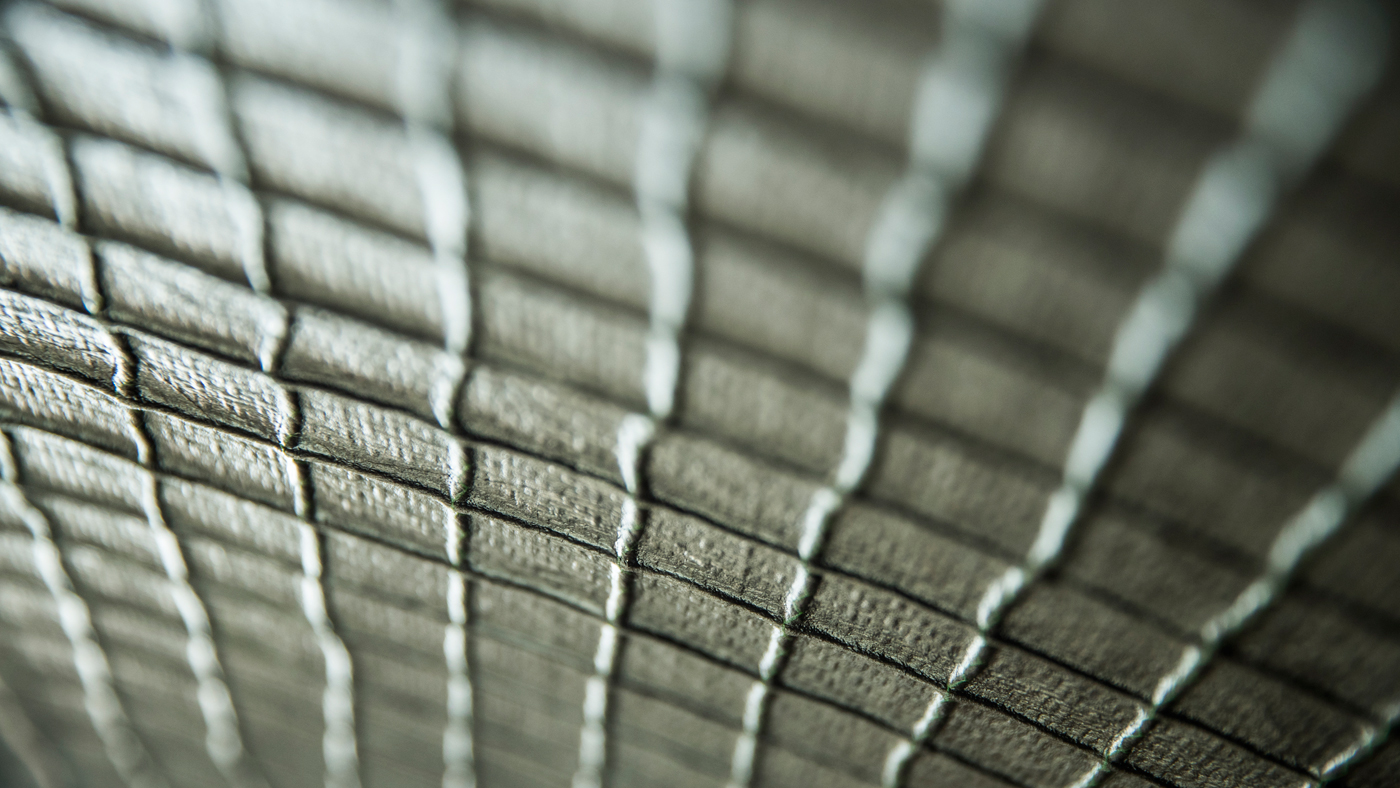

Pekka Laurila is pictured here with two flax samples, the larger one a floorboard with a flax laminate over a foam core, finished with a thin wood veneer. The smaller sample shows flax with a clear varnish finish and balsa core as an alternative for cladding.

INTERIOR

We have already used natural fibres for interior components, notably aboard Baltic 130 My Song, delivered in 2016. As a genuine multi-role superyacht, My Song’s weight control was critical and as a luxury cruising platform her noise levels needed to be low. With these criteria in mind, natural fibres was used in her floorboards, ceiling panels, certain table surfaces and a number of deck components.