Building a super sailing yacht with Baltic Yachts

21 July 2022

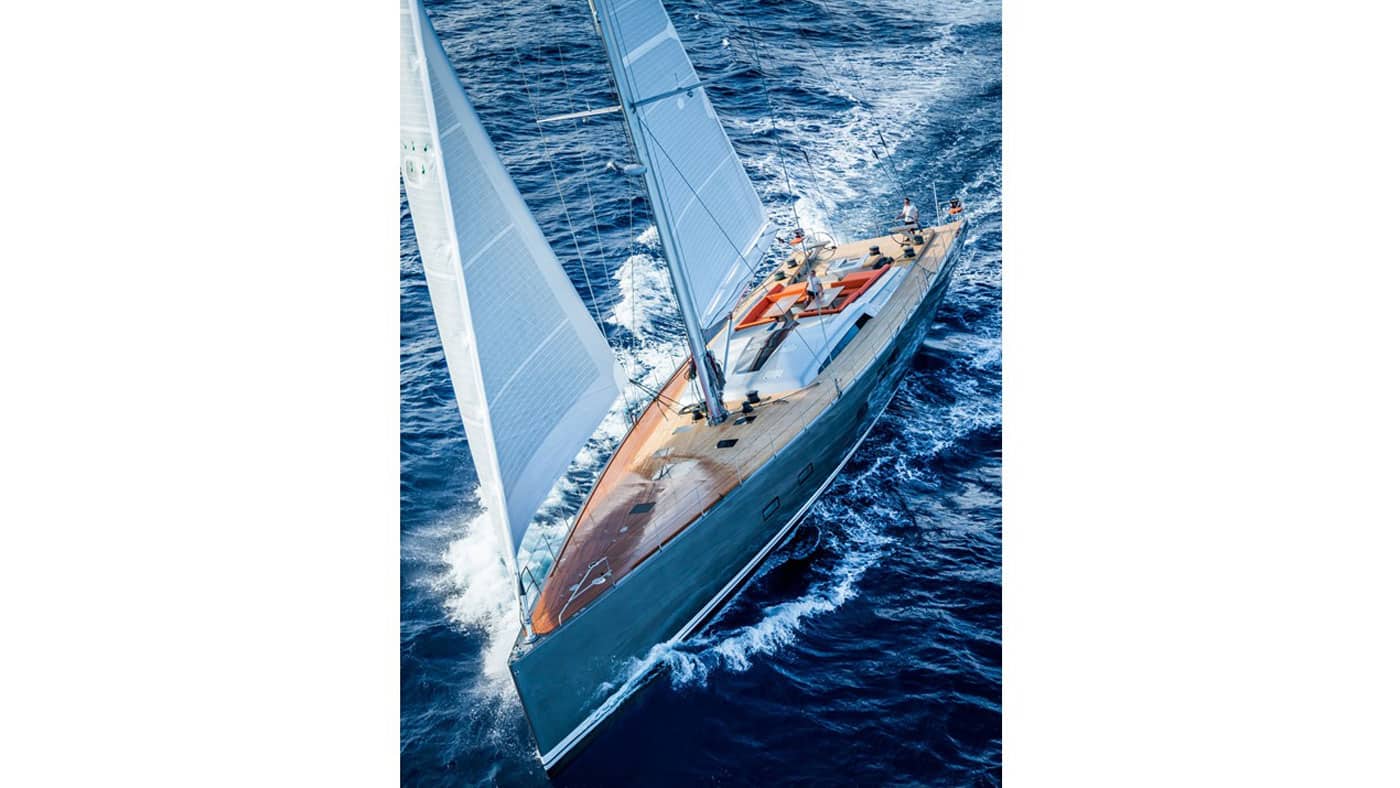

Baltic Yachts has mastered the complexity of building unique superyachts for clients who trust the company’s open-minded attitude and willingness to take on the seemingly impossible

Building a large sailing yacht is arguably one of the most rewarding and challenging feats of modern design and engineering, not least because a superyacht’s luxury accommodation and systems, supported by leading edge electronic technology, have to perform as a mobile living space in one of the planet’s harshest environments – the sea. A world leading exponent of this specialist skill is Baltic Yachts, based in Jakobstad.

Clients are attracted by the company’s unique ability to build in advanced custom composite materials – ideal for sailing yachts – its innovative approach to problem solving, a determination to leave no stone unturned in its quest for new ideas and an honest, open-minded attitude throughout the design and build process.

Beneath what one recognises outwardly as a refined sailing yacht, lies almost unimaginable complexity, from the construction of the hull shell itself to the sailing systems and all the modern conveniences one would expect to find in a land-based, luxurious house. No two yachts built Baltic Yachts are the same.

Making the process understandable and enjoyable

Establishing the team to build such a yacht and having a clear idea from the outset of what it should provide the client, are critical to the success of a superyacht building project. Baltic Yachts’ Executive Vice President, Henry Hawkins, said: “This is where Baltic Yachts’ down to earth approach really comes into its own, making the process understandable and enjoyable.“

Founded almost 50 years ago, the company has flourished this century as clients demand more complex combinations of improved sailing performance and ultra-comfortable living spaces for family and friends to travel the world independently.

They also want something unique.

One of Baltic’s key offerings is customisation. An owner can rest assured that he or she is in possession of a unique, exquisite product built to unmatched standards. There is an element of ‘must have’ about a Baltic.”

‘We listen and then together we build their yacht’

The genesis of a yacht commonly involves the owner discussing their next move with a naval architect whose work they are familiar with, the captain of their current yacht, a trusted broker or a professional project manager. But in the case of Baltic Yachts, clients often make a direct approach, aware that the company has a reputation for open and honest advice with the intention of building a bespoke yacht with no preconceived ideas that might suit a shipyard template. Elisabet Holm, Baltic Yachts’ Head of Marketing said: “They visit us, we listen and then together we evolve their yacht starting with a blank piece of paper – we don’t ‘force’ anything on the client.”

More than 40 years’ experience

Baltic’s expertise in working with advanced composite materials to produce the lightest, stiffest and strongest sailing yachts, has evolved over more than 40 years. Combined with the indigenous skill sets found in Ostrobothnia, honed over centuries, and a can-do attitude which embraces innovation and customisation, the Baltic Yachts’ offering is hard to match.

Although almost all Baltic yachts are multi-role, in that they are as much at home on the race course as they are cruising the oceans of the world, one only has to look at superyacht regatta results to see how successful they have been in competitive mode. Most owners are naturally competitive and even if they don’t intend to enter regattas, simply knowing that they are in possession of a yacht that is capable of winning is a subliminal attraction.

Although some would say Baltic Yachts’ location just 200 miles south of the Arctic Circle is difficult to access, most clients appreciate the relative remoteness and certainly enjoy the close-knit Baltic Family attitude generated by it. The sheer beauty of the area, with the intense differences overlaid by winter and summer weather conditions makes visiting Jakobstad and its surroundings an experience in itself.

There is an interesting parallel to be drawn with New Zealand’s famous yacht building operations and sailing achievements. Located in a similarly remote location, the New Zealanders also have a can-do, problem-solving attitude. Both countries have a pioneering spirit born out of their need to go it alone and Baltic Yachts, more than most, has exploited this to the full in the northern hemisphere.

Henry Hawkins, Executive Vice President and Elisabet Holm, Head of Marketing

Listening to the owner’s wishes

An owner’s first meeting in Baltic’s modern waterside offices and shipyard, overlooking the lacework of islands and shores that make up the stunning local coastline, will often involve experts from various departments. Their first task is to listen to the owner’s wishes and give a measured response as to what is possible and what might need further investigation. Personnel on hand could include: Kim Kolam, senior electrical engineer; Mikael Strengell, head of design and an expert in heating, ventilation and air conditioning; Patrik Högnabba, interior designer and Mikael Nyberg, engine, vibration and sound insulation engineer.

“This is a vitally important stage of the project with the majority of planning and design needing to be finalised before building actually starts,” said Henry Hawkins. “It’s also where parameters are set, any early conflict solving takes place and frameworks are established. It’s the start of a successful partnership and can only be achieved by having the best people, the best materials and ideas.”

It could also be said this is where guidance is on offer to help the owner to take those first tentative steps. “At this stage it’s important to note that we, as yacht builders, are very open and enjoy learning and working with our clients who are keen to push technological boundaries and explore new ways of doing things on yachts, many of whom have experience and ideas that will improve and enhance the product. However, we mustn’t lose sight of the fact that we are essentially in the leisure industry.” said Henry Hawkins. “The number one aim is to ensure it is an enjoyable experience!”

Taking on the impossible

That accepted, Baltic Yachts has a reputation for taking on what, at first, might look like the impossible. It could be a sliding hydrofoil in the hull of a 142ft yacht, fold-open balconies in the sides of a hull, the latest electric propulsion, propellers that retract into the bottom of the boat, cinemas, discotheques, swimming pools, remote control steering or press-button handling for sails the size of a couple of tennis courts. And in the pursuit of performance Baltic Yachts might explore an ultra-light superyacht employing technology only seen at the extreme limits of sailing yacht design.

The building process

Unlike a production boat builder, in which multiple, identical hulls are laminated in the same mould, each Baltic yacht is different, requiring unique, bespoke hull and deck moulds. In this way the company is able to accommodate precisely what a client requires.

Once the lines or shape of the yacht’s hull have been agreed, highly accurate computerised drawings will be transferred to the shop floor where skilled woodworkers will build a full-size wooden plug, shaped like the yacht’s hull, from which a mould will eventually be taken. The actual hull of the yacht will then be laminated inside the highly finished mould and eventually released before the remaining yacht building processes begins. The same goes for the deck.

Hull materials vary, but Baltic Yachts, more than most, is constantly evolving their use to achieve the strongest, lightest and stiffest structure. Stiffness is vitally important because the hull shape must be maintained, particularly when dynamic loads are imposed when sailing. Again, this is fundamental to Baltic’s belief in how to deliver the best performance by using its deep engineering resource and historical analysis to get the right results.

The company recognises, however, that external expertise will help them achieve their goals and composite specialist engineers like Swiss-based Gurit and Pure Design and Engineering in New Zealand work closely with Baltic on many projects.

Appreciating the hidden detail

“This is one of the areas where Baltic excels, in the hidden detail – for instance, an owner’s physical height might determine much of the accommodation design, something that cannot be done in a more production orientated shipyard,” said Henry Hawkins. “And in one of the yachts we’re building right now we had the client’s entire family sitting around a mocked-up cockpit dining table so that we could get seat backrest angles and heights precisely right. It is detail like this that makes a difference.”

Systems engineering is an immense part of the building process and includes everything from hydraulics and entertainment systems to propulsion, electricity generation and plumbing.

Capitalising on new technology

One of the biggest advances has been in electric propulsion systems and means of generating electricity other than using fossil-fuel burning generators. Again, a great deal of work has been done with external experts, trusted suppliers and a network of global contacts. “We are often approached by companies who want to partner with us. The electrified powertrain specialists, Danfoss, the Danish engineering giant and Polestar, the Swedish electric car manufacturers among them,” said Henry Hawkins.

Engine rooms on sailing yachts have changed completely in only the last few years, with powerful, compact electric motors replacing internal combustion engines and Lithium-ion battery banks charged by the propeller driving the propulsion motor as a generator while the yacht is sailing.

By burning less fossil fuel this has dramatically reduced emissions, vibration and sound levels making superyacht sailing quieter, cleaner and more sustainable.

Remaining part of the Baltic Family

For most yachts over 30m it takes close to three years to complete the build, trials and delivery before departing the waters of Jakobstad. Theses yachts, as do all that came before, remain part of the Baltic Family for the rest of their lives with the company’s important Service and Refit operation available to them worldwide.

Baltic-built yachts have circumnavigated the world, sailed deep into both polar regions and recently one of their largest, made her way through the North West Passage. They have won regattas in Antigua, St Baths, Sardinia and Mallorca and have taken part in some of the classic ocean races like The Rolex Fastnet, RORC Caribbean 600 and the Rolex Middle Sea Race. They have won almost 30 international awards for design and innovation and have regularly picked up the Yacht of the Year Award, the ‘Oscar’ of yacht design.

They are custom yachts for all seasons and all oceans and admired wherever they choose to drop anchor but most of all they are loved by their owners.

MORE ABOUT US

PERSEVERANCE WINS ECO AWARD FOR RANGE OF POWER SAVING INNOVATIONS

Baltic 117 Perseverance wins Eco and Best Naval Architecture categories in design awards, as Gerard Dijkstra is recognised for Lifetime...

MORE

THE BALTIC LOG SPRING 2022

Welcome to the spring 2022 edition of the Baltic Log, your personal update on Baltic Yachts’ news. ...

MORE