Tell Tales: 83FT CRUISING

7 April 2022

Many of the projects we have produced through the years has left valuable memories in our memory bank. We have done everything from extreme racing, performance cruising projects, with extensive weight saving in order to achieve the clients’ and our own goals. We have also done projects where the extreme performance has not been the top goal, instead more emphasis on cruising comfort.

One of the more cruising minded projects we did in the mid. 1980: s was an 83 FT custom performance cruiser. Our Italian agent, at the time, Roberto Fabbri got in contact with a central European client that showed interest in having an 80+ footer built. We visited the client, in Switzerland, and talked about his vision for his new project and based on that I went back to Finland with an information package as a base for creating preliminary drawings, layouts, specification, weight studies and price calculations.

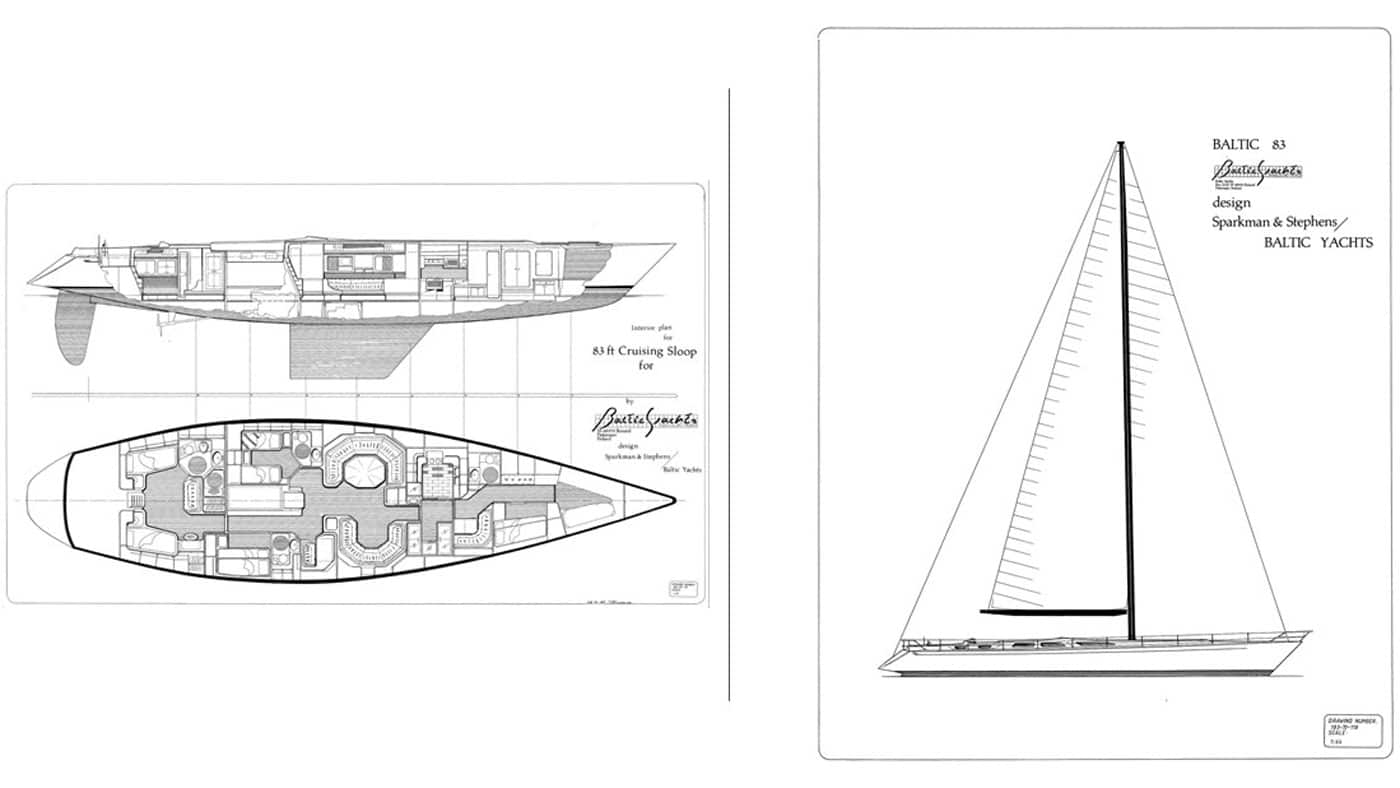

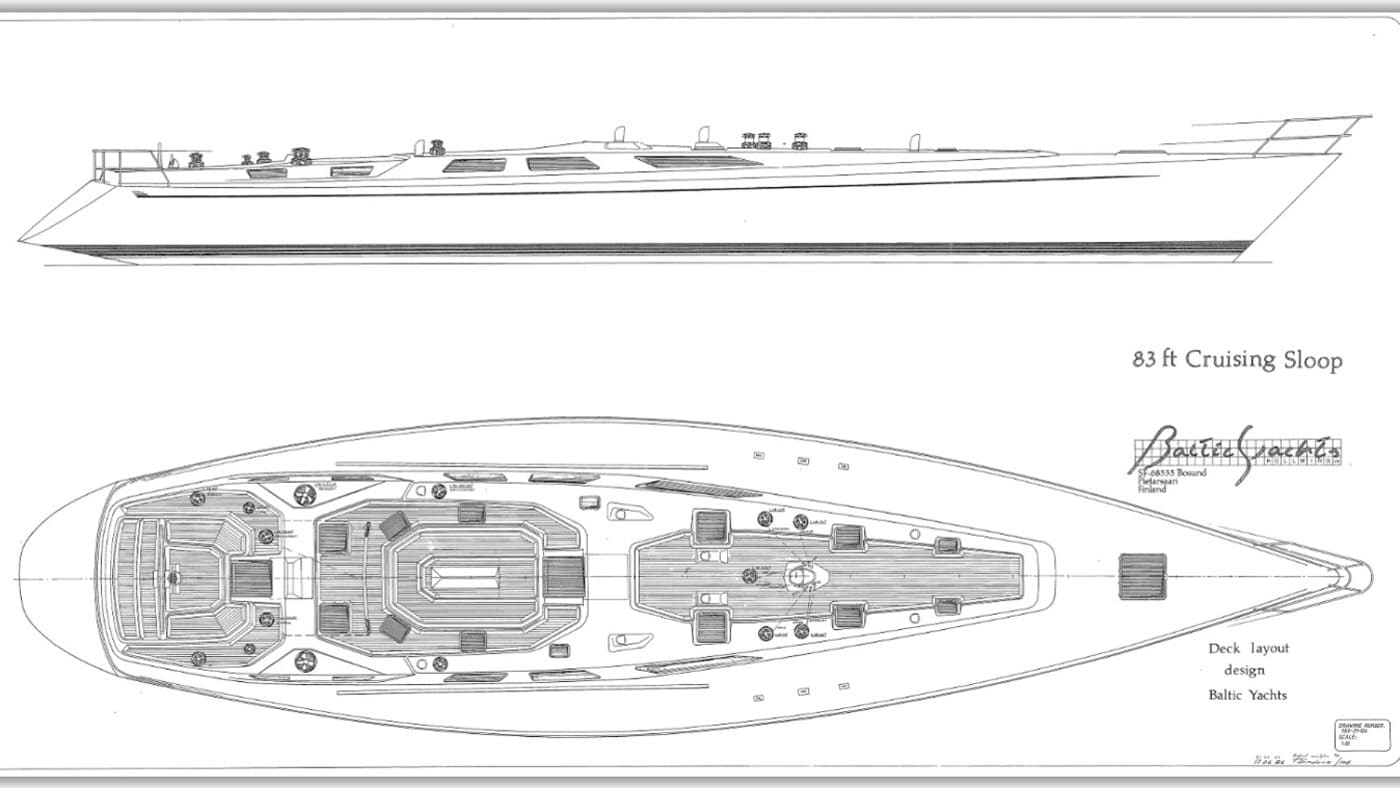

This was, at the time, our largest projects so for that time in our history it was a challenge. Our In-House-Engineering people looked forward to the challenge with great enthusiasm. In the discussions with the potential client, we had touched the bases of alternatives for Naval Architecture. The client was leaning toward Sparkman Stephens and based on this we contacted S&S asking if they would be willing to produce preliminary hull lines for the project. Based on lines we got from S&S we produced deck layouts and styling as well as interior layout alternatives. There were a number of layouts and suggestions flying back and forth between the client and ourselves and after a number of months working, we had a design package ready for presentation.

With this package plus a preliminary contract proposal in my briefcase I met, together with Roberto Fabbri, with the client. After a full day of discussions, I flew back to Finland with a signed contract and a bottle of wine from the client’s vineyard. It was a good feeling that months of team effort, from our side, had resulted in a very good contract. For your information: I have never tasted a better wine.

We immediately started the project. First project with Sparkman & Stephens and our largest project at the time.

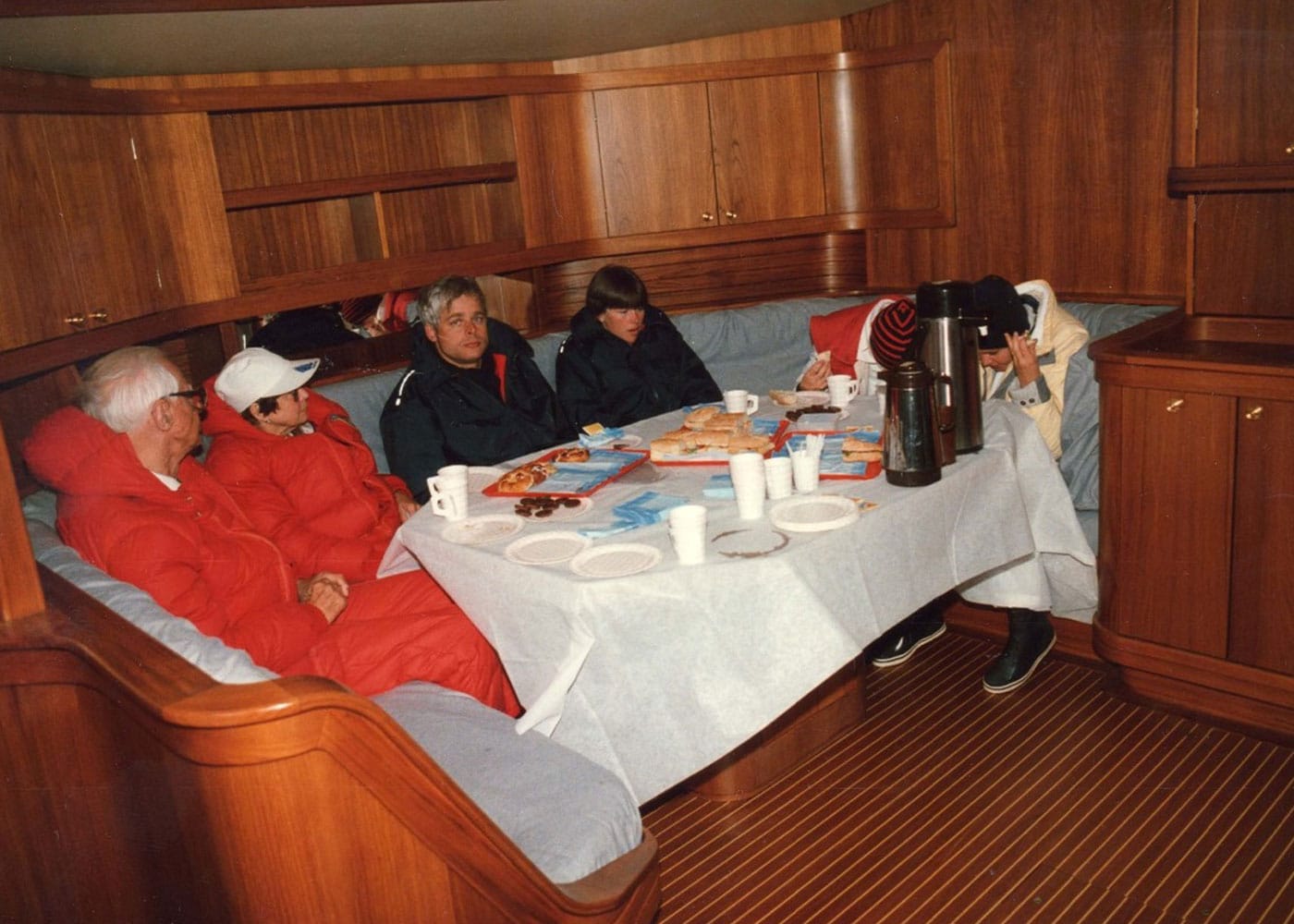

As mentioned earlier, the main emphasis for this project was cruising comfort. However, good sailing characteristics were not off the table hence hull and deck were sandwich construction and unidirectional fibers. The interior was also built fairly light. The result was a very comfortable cruising yacht but with very good sailing characteristics. The interior was very detailed with cold-molded frames and surfaces in all directions. Our chief designer, at the time, Tor Hinders, took things to the extreme hence our interior carpenters faced a challenge. But as can be seen from the enclosed pictures they more than lived up to the challenge.

There are naturally many interesting things that take place during a project like this, but it is difficult to remember and retrieve those things from an old persons defected memory bank so most of them will remain untold.

One thing I do remember is a small (very small) incident we had with the main engine. The main engine was a 280 hp Mercedes Benz diesel. The marinization was done by a small German company and by the time we got close to launching they informed us that we were not allowed to start the engine without their representative being present. In our opinion this was ridiculous, starting a small engine like this should be routine but the engine supplier was very insistent. I told him that if he insisted, he should have his representative present and gave him a date. We had a team of people, subcontractors etc. on standby and had no time for fussing around with a small diesel engine. In the final end he gave up on a rep being available but insisted that a person from one of the German equipment suppliers, that was at our yard at the time, should be present and oversee the start up. This person looked at me and told me that he had full confidence in us and that we, in his opinion, was far more knowledgeable than him to do this. So, we checked the engine oil and cooling water, checked that the cooling water seacock was opened, run the starting motor (without starting) for a few second and stated the engine, checked that oil pressure was OK and moved the boat to our equipment pier. We had a good laugh about the situation and decided that, in the future, we probably should avoid doing business with this company.

But like always in life, you run into compromises and so did we. Some years later we did install engines (much larger) from the same supplier but this time without the extra hassle.

The launching of the yacht was followed by days of preparation and testing. We were out with equipment suppliers, sail makers etc. We also had the opportunity to sail with members from the press and even a couple of days with invited Baltic Yacht clients.

Another very small incident took place with the propeller. The yacht had a cruising 3-bladed feathering prop, very simple and very basic. The propeller manufacturer had calculated the pitch and after the first test we noticed that the engine could not reach maximum revolutions, the pitch was too large. This was a type of propeller where the pitch was not easily adjustable. The blade angle (pitch) was determined by the blade stopper position. All very simple and external, hence reachable. The manufacturer apologized for the mistake but promised to correct the pitch if we sent them the propeller for modifications. According to them we were not allowed to make these adjustments ourselves. Unfortunately, the propeller manufacturer was in North America, and this would delay the testing and delivery of the project. Since the needed adjustments, in our eyes, were fairly straight forward we decided to make the necessary adjustments ourselves and avoid the delay.

We did our own calculations on how much the blade stop surfaces needed to be adjusted in order to reach the correct pitch, had divers go down and remove the prop (which they did very effectively) and planned to send the prop to a nearby machine shop for the work. One of our all-round boatbuilders, he could be used for any kind of jobs, laminating, engine work, electric carpenter etc, looked at me and said: if you send this to the machine shop it will take the rest of the day before we have it back, I can do this job with hand-tools in 15 minutes and the divers can re-install the prop immediately. We gave him the job and it was done in less than 15 minutes. I asked him: are you sure that all three blades have the same pitch? He looked at me and raised his eyebrows and I apologized for asking that question. The propeller was immediately installed, and we went out for testing and had a perfect pitch and smooth running. It’s nice to be surrounded by good people, it often makes life simpler.

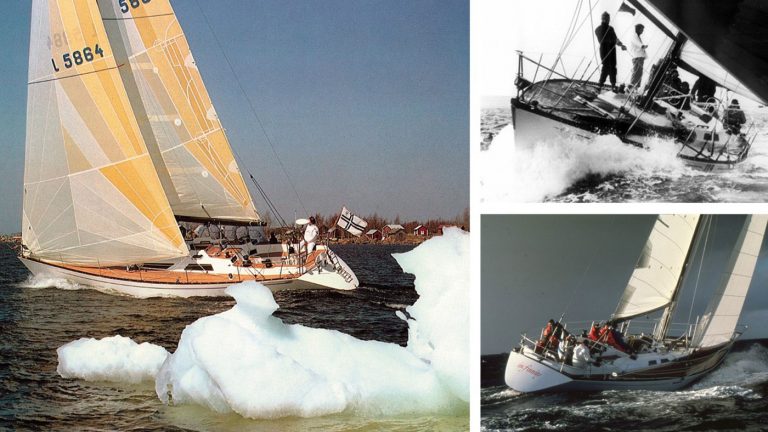

For the next days we did a lot of testing and sailing. Things proceeded so well that we had some time over for sailing with photographers, press and at the end also with invited guests.

This was in early spring, April, and this can be a time, in Finland, when sailing might not be possible due to ice situation but this year it was possible but occasionally very cold. One day we invited, local Baltic owners and guests for a sail.

As can be seen from the photos, not the best possible weather for sailing but we enjoyed it and I do believe that our guests also did.

In spite of the cold weather, we managed to take a number of photos from this sailing activities. Peter Neumann, Yacht Photo Service, was present and had his own dinghy brought up to Finland for this purpose. I believe that he also took video films but unfortunately, I could not find them, otherwise they would be part of this story.

On the first of May 1987, the boat left Finland on a course towards a warmer and more enjoyable sailing climate.

In 1980: s the 83-footer was our largest project so far. In an international view it was also a large project. A nice client, good subcontractors, a tremendous yard team, the result was a very nice cruising yacht with very good sailing characteristics. It represented one of many milestones in the history of Baltic Yachts.

Another valuable item in my memory bank.

TELL TALES

PG JOHANSSON

There can be few yacht builders like PG Johansson, who can boast an unbroken career with the company he co-founded almost 50 years ago. In that time PG Johansson has witnessed every twist and turn of a colourful, exciting and technically pioneering industry accumulating a wealth of fascinating stories, some familiar, some still untold. In this blog PG will be recalling his experiences of the yachts he has built, the people he has met and some of the more unusual events on the journey to turning clients’ dreams into reality.

Would you like to comment on this post or share your own Baltic story? Join our ‘Baltic Yachts Tell Tales’ facebook group exclusive to the Baltic Family.

PREVIOUS BLOG POSTS

TELL TALES: LISTEN TO YOUR CLIENT

In my previous blog I covered mainly our serial production models and the reason/reasons why we, during later years, moved...

MORE

TELL TALES: FOLLOW YOUR HEART

Looking back at Baltic Yachts history and going trough the files and statistics of all the project that has been...

MORE