Tell Tales: Challenging projects with great teams

9 September 2021

As mentioned earlier, one of the most rewarding things, in our segment of the yachting business, is the interesting and very special clients one has the opportunity and honour to meet. And in addition, the very challenging but interesting projects these clients give us. Very interesting, knowledgeable but demanding clients, looking for projects that are beyond the horizon for most people.

Most of these clients are very experienced sailors with a high degree of technical knowledge and with an urge to be involved in developing something new, second to none. All of them enjoy sailing but they also, very much, enjoy the process of developing, being involved, building, and creating something new, their dream.

I remember once we were out for the first test sailing, with the client onboard. Everything went perfect, and the client was very happy, a dream fulfilled. Coming back into the harbor the client looked at me and asked: so, what do we do next? He then smiled and commented that he should probably enjoy his new boat for a couple of years before starting a new project. Just an example on the level of involvement.

In 1992 we delivered a Baltic 58 to a Mediterranean client. This was for its time a high-performance boat and the client was very successful on the racing scene which gave us very good publicity.

Some years later we delivered, for the same client, a custom Baltic 67. A Bruce Farr designed, full carbon project. According to our material supplier, this was one of the largest carbon laminates in the World at the time.

After a few seasons of successful Mediterranean sailing the yacht was sold to Germany and named UCA. In Germany the yacht continued to prove its speed potential. In year 2000, with our agent Walter Meier-Kothe in the crew, UCA won the 510 nautical miles, Around Skagen Race. Not only did they win, but they also broke the old record with stunning 11 hours less sailing time than the previous record holder.

In the meantime, the original Mediterranean owner had a new project in mind. He was in contact with our Italian agent, Alessandro Vismara, and had the idea of a high-tech, high-performance, canting keel project in the 75-80 FT size. At that time some of the extreme empty sailing machines had started to use so called canting keels enabling them to cant the keel 35-45 degree to the side creating high stability with less ballast weight. Those yachts had no interior hence the canting keel pivoting arm could protrude substantially into the hull allowing for a longer pivoting arm and reduced pivoting force.

Our clients’ ideas were slightly different. He was looking for a full cruising interior, a sleek low freeboard hull. And his goal was to have the mechanism for the canting of the keel under the floorboard. We had a preliminary meeting, 12 December 1997, at the client’s house. Participating in that meeting was the client, Alessandro Vismara, John Reichel and Jim Pugh from Reichel/Pugh Yacht design, Giovanni Belgrano from SP System (composite supplier and engineering) and myself.

One of the main challenges with the canting keel system was the fact that it all had to be none visible in the interior with the whole pivoting mechanism under the floorboard level, resulting in a short pivoting arm therefore very high load. I remember the first calculations we did and the numbers we came up with indicating strongly that it would not be possible. However, after fiddling around with slightly higher freeboards, less headroom, giving us higher floorboards etc. we could come up with numbers that were realistic and achievable. The engineering was on its way and order signed.

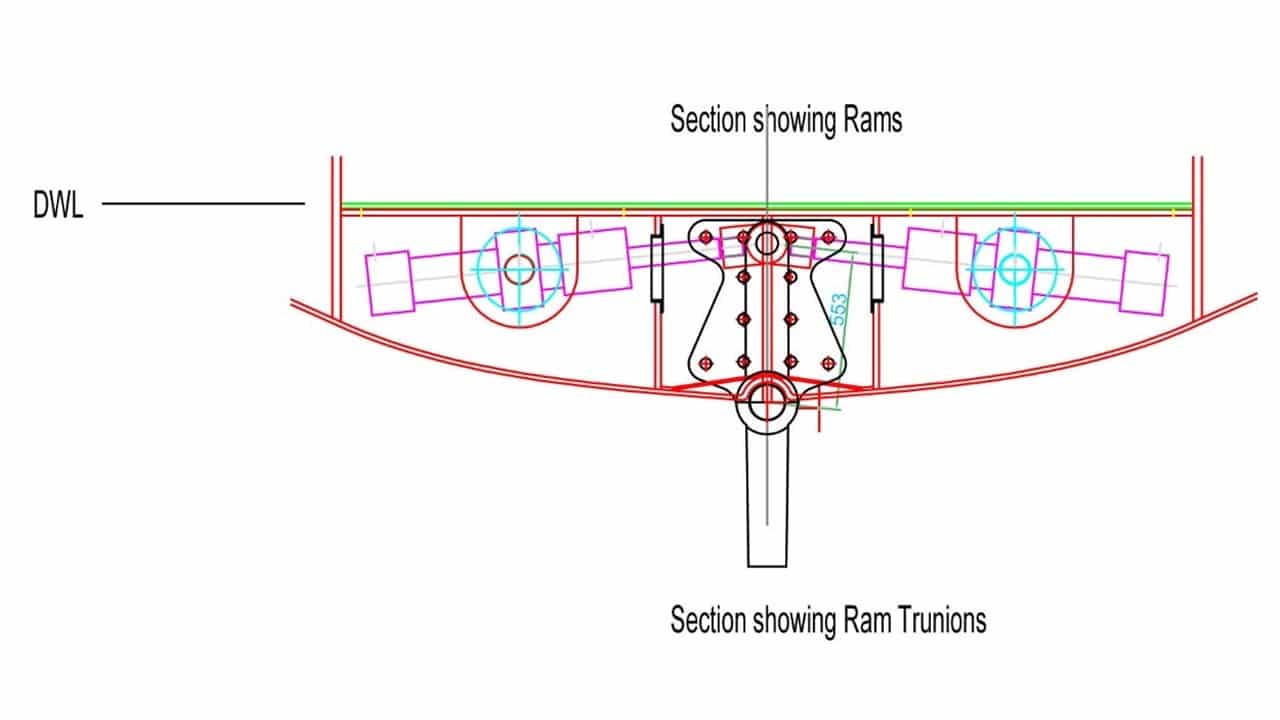

Section showing keel-canting system including hydraulic rams.

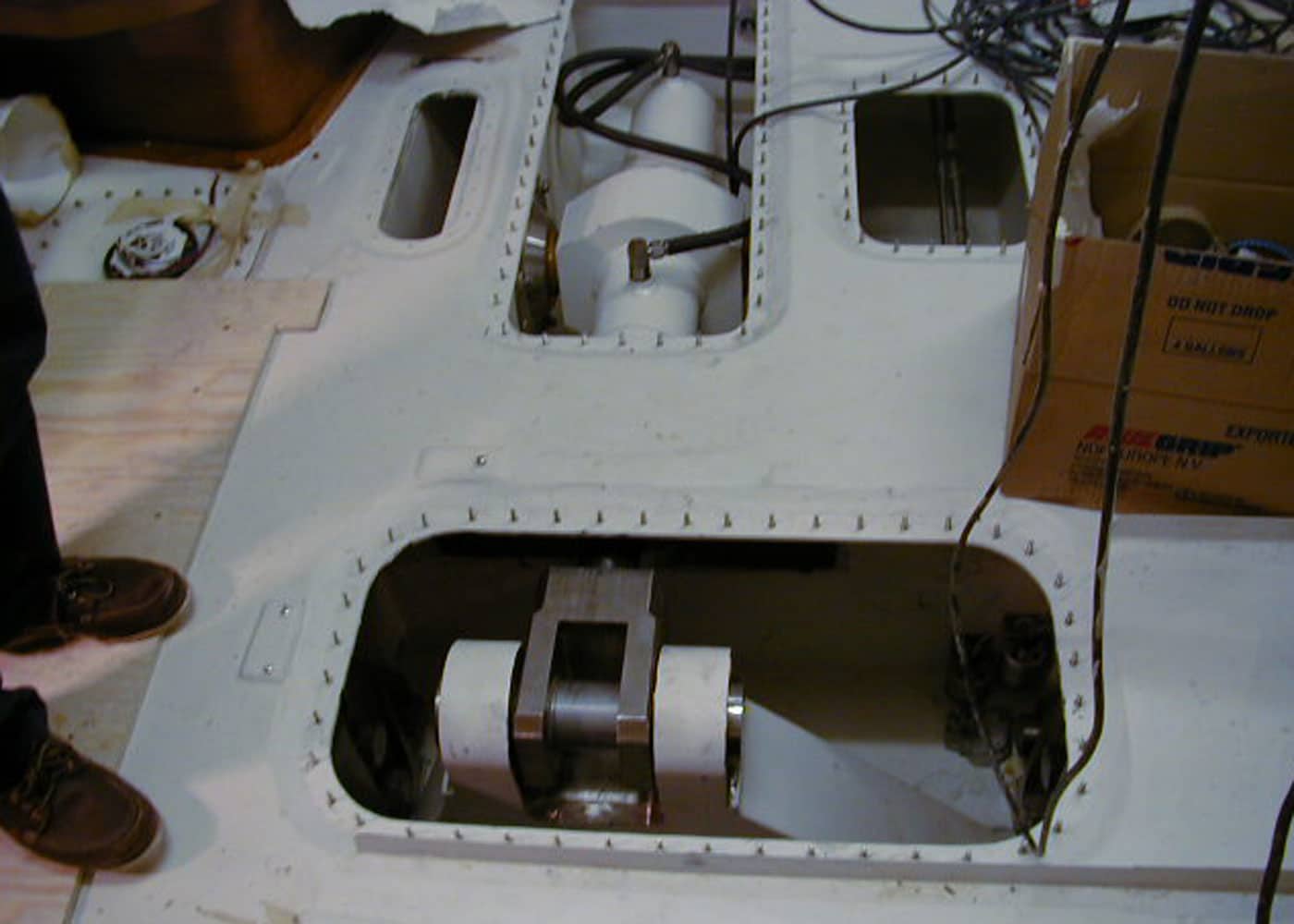

Keel fin prepared for installation (left) Keel hinge pins installed (right)

I remember when we installed the keel fin. The fore and aft hinge fins were passed through the bearings/endplates into their space in the keel fin. The hinge pins and the seat in the keel were very slightly tapered. To get the hinge pins into their right positions we needed to create a temperature delta between the pins and the keel of approx. 100 Centigrade. In order to reach this temperature difference, we used liquid Hydrogen to cool the pins down. This allowed the hinge pins to move approx. 3.5 – 4.0 mm further is than with equal temperatures. This created a very strong and rigid bound. Just one example of many special methods used in this project.

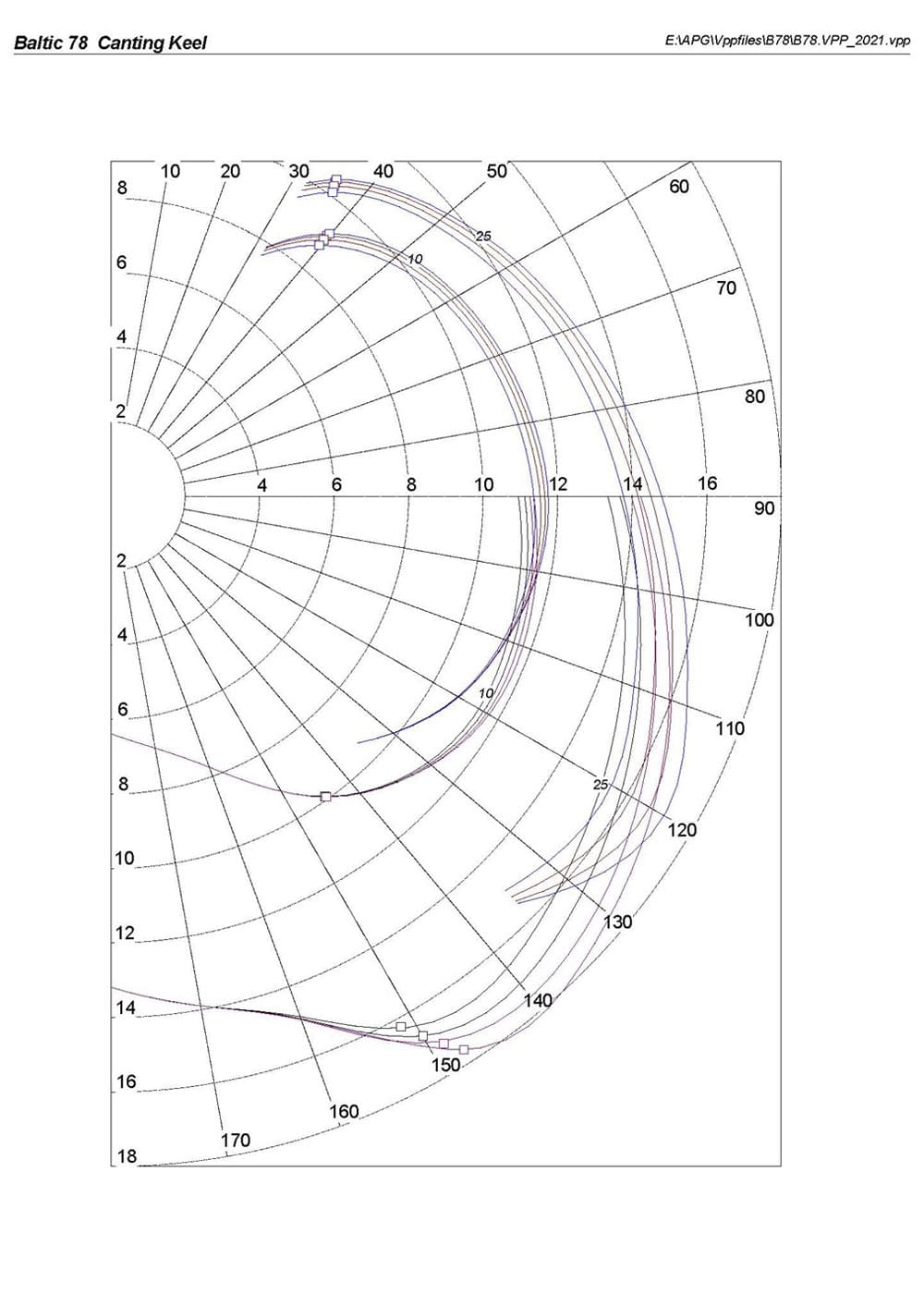

Simplified Polar Plot (using only two wind strengths for simplicity) showing the influence in boat speed, at different keel canting angles.

In addition to the canting keel, the project was also in all other areas very high-tech. Emphasis was to save weight wherever possible by using best materials and methods available. Hull and deck were full carbon Pre-Preg laminates cured under vacuum in an oven at 90 C temperature. Honeycomb, Nomex was used as sandwich materials in hull and deck. Just to mention some of the weigh saving efforts.

The result was a full interior, comfortable cruising boat with very high performance and racing potentials.

When I look back on this project and go through all the information, drawings, calculations, etc., I must once again state that I am very impressed with the performance that the Baltic Yachts organization has achieved. Everyone from boat builders, foremen, project managers, designers, etc. has done an enormous amount of professional work. For me personally, it is a great honor to have had the privilege of working in such a team.

However, it is quite clear to me that in order to be able to perform and carry out a project of this caliber, you are also very much dependent on people and companies outside your own organization. One cannot “invent the wheel” every time, you must be very open to the use of outside expertise. This is very clear, especially with extreme projects like this. This project team included several companies and individuals who to a large extent contributed to the project being carried out in an efficient and professional manner. I cannot name everyone who contributed but to mention a few:

-

- Naval architect Reichel/Pugh. Very professional and supportive.

- SP System. Specialists in composite construction and materials with valuable experience from some of the canting keel racing machines.

- Ward Proctor. Our innovative and knowledgeable hydraulic specialist and supplier. With valuable experience from some of the canting keel racing machines.

- Alessandro Vismara. Our Italian agent with a lot of knowledge, ideas and visions.

- And most important, the client. With his knowledge, visions and dreams, he gave us the opportunity, responsibility and possibility to be involved and produce a very outstanding project.

This project was delivered year 2000 and was our first canting keel project. As a matter of fact, we have built only two canting keel yachts. The second one was a Baltic 56 built a few years later. We have made studies for other projects, but they were larger in size. The problems with the larger boats were that with a “normal” canting keel the keel depth end up in numbers that some marinas cannot take. To solve this issue, one would have to make a lifting canting keel. We did some preliminary drawings for this and concluded that can be done but would be very complex and heavy hence questionable if it is worthwhile.

Anyhow, the Baltic 78 was a very memorable project with a special place in my memory files. Great people involved, at the yard and also outside designers and suppliers plus a very knowledgeable client.

A GREAT TEAM.

TELL TALES

PG JOHANSSON

There can be few yacht builders like PG Johansson, who can boast an unbroken career with the company he co-founded almost 50 years ago. In that time PG Johansson has witnessed every twist and turn of a colourful, exciting and technically pioneering industry accumulating a wealth of fascinating stories, some familiar, some still untold. In this blog PG will be recalling his experiences of the yachts he has built, the people he has met and some of the more unusual events on the journey to turning clients’ dreams into reality.

Would you like to comment on this post or share your own Baltic story? Join our ‘Baltic Yachts Tell Tales’ facebook group exclusive to the Baltic Family.