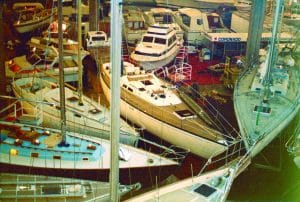

THE WORLD OF BALTIC YACHTS

We are world leaders in advanced composite yacht building. We combine leading edge design and engineering with innovation and traditional craftsmanship to provide clients with the ultimate experience in performance and comfort afloat.

If you dream of cruising the oceans of the world with your family and friends or competing on the most exciting race courses, we can provide you with the means to make that dream come true.

For 50 years we have built yachts that are lighter and more technically advanced to gain performance superiority over the competition. In short, Baltic Yachts build yachts that are lighter, stiffer and faster. And to consistently achieve this we work closely together as a team alongside business partners who are experts in their fields.

LOCAL CRAFTSMANSHIP

Our yachts are hand-built with pride, using traditional craftsmanship. From the custom-built advanced composite hulls and decks to the exquisite lightweight timber accommodation finish, every yacht benefits from the deep-rooted skills found in our workforce. Many are from the local region of Ostrobothnia where shipbuilding has existed for generations.

THE UNSEEN QUALITY

From super-lightweight cabin furniture and shock absorbing pipe supports to advanced sound deadening materials and integrated fuel tanks, the unseen quality on any Baltic yacht doesn’t often make the headlines. But it is this standard of work that provides every Baltic yacht with the reliability and quality that keeps it functioning in the harshest environments. Baltic Yachts is constantly looking for better ways of designing and installing the myriad systems a yacht depends on. Reducing vibration to cut noise levels is just one of the many objectives of good installation design. Reducing weight by using advanced composites is another. Baltic Yachts’ designers and engineers have become experts in these and other fields.

WORKING WITH BALTIC YACHTS

I like working with Baltic Yachts because of their excellent know-how in carbon composite yacht building that is very difficult to find elsewhere. Our team also appreciates the diligence and fairness they have shown in selecting the correct products and suppliers for each build project we have worked on together.

Sebastian Allebrodt, A2B Maritime Consulting

MM341 is the first MMYD design to build with Baltic Yachts. The build process has been significantly enhanced by the yard’s meticulous and intuitive methods.

As a design studio, we have appreciated Baltic Yachts’ inclusive team approach and feel sure that this results in the most successful superyacht projects.

Malcolm McKeon, Naval Architect Malcolm McKeon Yacht Design

Designing the Baltic 142 Custom has been a unique experience. We worked with the owner to improve comfort on board and to maximise performance. At Baltic Yachts I found a team of people with a new vision who embraced the environmental and lifestyle concepts we were trying to achieve.

It was great to work with them on the overall aesthetic of the yacht and with the design and engineering teams, developing everything from the acoustics and lighting to the installation of the DSS and the electric propulsion system. Today technology allows us to take a different approach to the maritime environment, enabling us to build ‘cleaner’ yachts which work in harmony with the people who sail them. The team at Baltic Yachts made this possible for us.

Lucio Micheletti, Architect Micheletti & Partners

CAREERS

We are constantly looking for new talents to join the Baltic Family. It’s an opportunity to work independently with a high end product in an innovative environment.

We are a team of experienced boat builders, who would support and encourage you to improve your skills and develop within the company.

Please visit our recruitment site and connect with us. (For now only in Swedish)

FINNISH BOAT BUILDING HERITAGE IN OSTROBOTHNIA

Five skilled boat builders set up Baltic Yachts in 1973 with a clear objective to build better yachts – lighter yachts, stiffer yachts, faster yachts. With more than 550 yachts launched that objective has been continuously met.

Drawing on the unique skills of our local craftsmen and the expertise of our designers and engineers we quickly established an international reputation for building high quality yachts which meet the requirements of our clients.

1973

The company is founded in Bosund by five young men

1974

The first Baltic 46 is unveiled at the Hamburg Boat Show

1975

First custom boat is delivered, Baltic 42 Tina-I-Punkt

1977

We deliver the first of our most popular model, the Baltic 39. We sell 74 hulls between 1977 and 1983.

Late 1970

The company starts making a lot of smaller components in carbon. We introduce carbon fibre rudder shafts to the cruising world and start using vacuum bagging for larger parts

1982

First maxi-sized project, Baltic 80 Midnight Sun

1997

First powerboat delivered, Baltic M48 Far Niente

2002

First boat over 100ft delivered, Baltic 147 Visione

2009

The Pietarsaari yard opens

2011

Baltic 197 Hetairos is delivered, at the time the largest composite carbon yacht in the world

2014

The Service & Refit centre in Palma opens

2017

The award winning Baltic 175 Pink Gin is delivered, the largest carbon sloop in the world

2018

The first Baltic 67 Performance Cruiser semi-custom sailing yacht is delivered

2019

Baltic 142 Canova, first superyacht to be equipped with a DSS foil

HISTORY

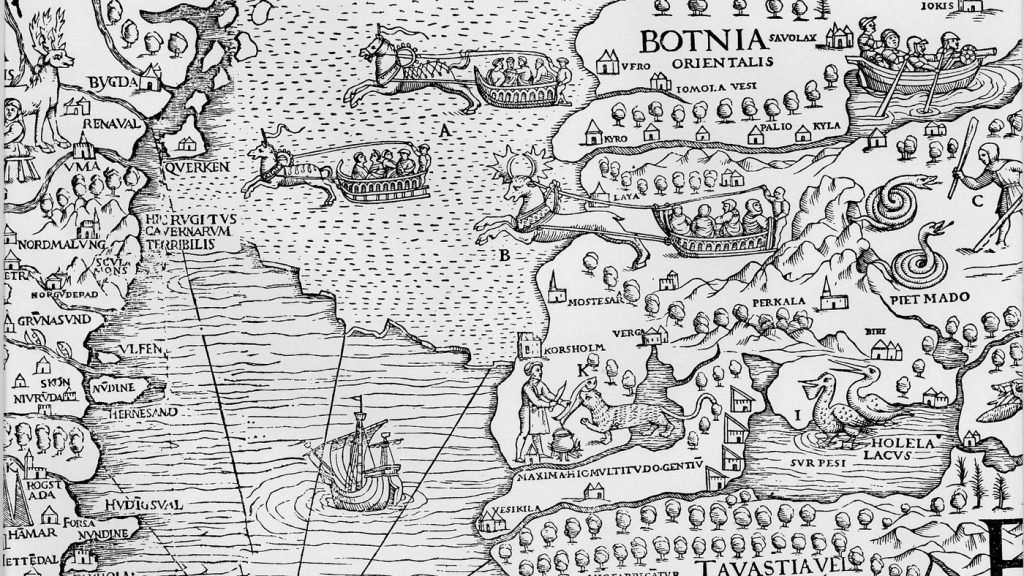

The importance of shipbuilding over many centuries and the seafaring communities which grew up around it, are fundamental to the existence of yacht building in Jakobstad as we see it today. The story of how the combination of timber and local woodworkers, whose skills have been passed down over generations, came to generate the biggest fleet of ships in Finland, is told in Jakobstad’s impressive town museum located in the Malm House.

It’s just part of a long history in which the Malm family played a leading role and in which the influence of seafarers from Jakobstad extended across the world.

Maritime connections

The impressive ship Hercules was owned by the Malm family and was the first Finnish ship to circumnavigate the world between 1844 and 1847. Peter Malm used local timber and woodworkers to help build his fleet of ships, the country’s largest. His business was badly affected by blockading during the Crimea War in the mid-1850s, but Peter’s son Otto helped re-build the business and by the late 1800s he had become the richest man in Finland.

Up until 1809 Finland was part of Sweden so the ability to make the sea passage between what is now the Gulf of Bothnia was essential. Ship building was arguably the most important industry in the area and this 16th Century chart clearly indicates the existence of ship building with the annotation ‘hic fabricator navalis’ – ‘ships are built here’ in the vicinity of Jakobstad. Large swathes of forest were also clearly shown.

Finland’s shipbuilding prowess saw the country’s seafarers travel the world, their experience often impressing the unwary. They would convince fellow seafarers that they could catch the wind and save it in a special knot – then sell it to them! They were skilful sailors and often in demand by those making some of the earliest and most daring voyages. Finn Herman Sporing was aboard Captain Cook’s Endeavour becoming one of the first Europeans to set foot on Australian soil.

MORE ABOUT US

Kenneth Nyfelt

Kenneth Nyfelt began his career at Baltic Yachts in the 1980s sweeping floors and carrying out small electrical tasks during...

MORE

Mikael Strengell

The Baltic design principle is based on functionality, flexibility and freedom. "This means we can offer our customers total freedom...

MORE